The Dilemma

It is hard enough to keep inventory turns high without parting out. Now imagine doing this if the consumption data from manufacturing is not accurate and timely. Keep tabs not only on only material flow but also precise real time actual material consumption.

The Solution

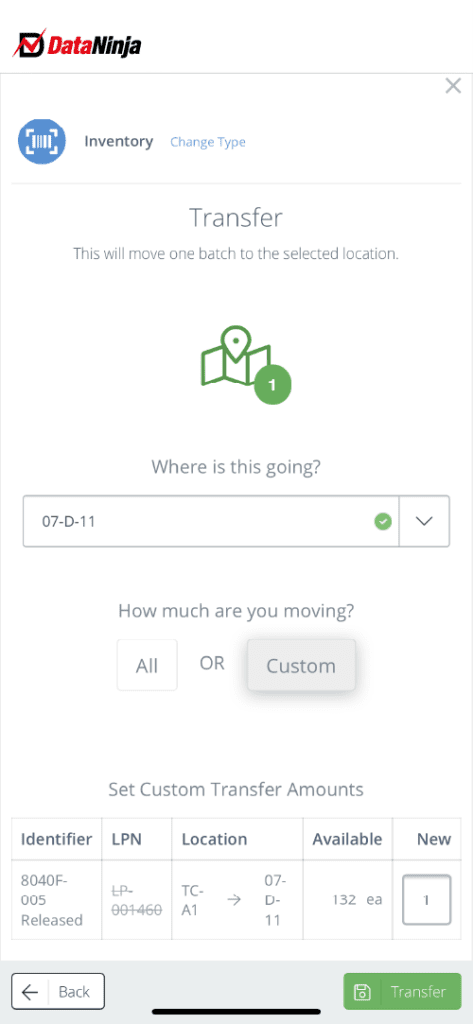

DataNinja brings key data from operations back into your ERP without the cost or errors of hand entry. From dock to dock the DataNinja kicks tablet based warehouse automation in high gear with versatile barcode options, visibility into transfers, and real time material consumption from manufacturing. DataNinja reduces the time investment for modern cycle counting and physical inventory efforts by tagging each box with a unique ID including quantity. Going paperless without manual data entry has never been so informative.

A solution for every role.

Imagine a software that is flexible, nimble, robust and powerful. Are those words you would use to describe your inventory control system? Introducing DataNinja.

- Tablet-based warehouse automaton with versatile barcoding options

- Automatic connection between ERP and warehouse transactions.

- Inventory is removed from Finance system in Real-Time, not days or weeks later

Over ordering is an enemy to your lean process, but operations come to a screeching halt if inventory levels run low. DataNinja can empower your purchasing strategy.

- Same raw material used in multiple finished goods? No problem

- Ensure that production using the right portion, of the correct material, every time

- Barcoding to track consumption in Real-Time

DataNinja extends practices of traceability from doc to the plant floor to limit risk and increase root cause analysis of manufacturing variability.

- Real-Time analysis engine DataNinja can trigger additional review and approvals, or, halt the escalated batch whenever key process variables are outside expected ranges.

- DataNinja delivers your data so yield analysis can become a powerful tool for your business.

- Identify trends and causes of manufacturing variability across Lots.

As a material handler production is second nature. Using DataNinja can help you stay ahead of busy work as you move production forward.

- Verify that the appropriate and released raw materials are being used with integrated 2D barcodes

- In the rare event of a missed transfer, the transaction is self-healing with subsequent transfers or consumption

- Cycle counting made easy. Go ahead and cycle count right in the middle of a shift.

DataNinja automates the shipping paperwork, and constantly checks to make sure the PO is precisely fulfilled. Now you can focus more on optimizing logistics.

- Generate shipping label and pallet barcodes

- Record multiple shipments against the same purchase order

- Automatically deduct inventory from warehouse location upon shipment

Questions? Lets talk.

Request Demo

MOBILE READY

Just scan the barcode

A smart sublot identifier barcoding system will let your team finally break past that “master” spreadsheet.

Controlled

You set the permissions, quality workflows, and escalation routes. Let your system bring the most critical issues to your attention automatically.

Integrated

Container specific barcodes tie quality release status directly to inventory. Real-time verification prevents process execution quality issues before they can happen.

Get started with your personalized demo.

See how it could work for you- book a demo with one of our experts and we’ll show you what the quality operations management platform can do.

Here’s what to do

+ Fill in your details and click “Submit”

+ We’ll get in touch to book a date and time

for a demo.

+ On the day, we’ll walk you through the platform

and show you how it all comes together.