Quality leadership has an immense responsibility to protect the consumer, customer, and company. Automate the simple checks with DataNinja; empower your staff to manage by exemption and focus on the most important issues.

- DataNinja is designed not just to collect your data, but to encourage people to increase quality

- Prevent rather than document costly errors

- DataNinja improves quality with out any extra busy work

Be confident in your system during audits. With DataNinja each record will have the required signatures, dates, calculations, approvals, and escalations.

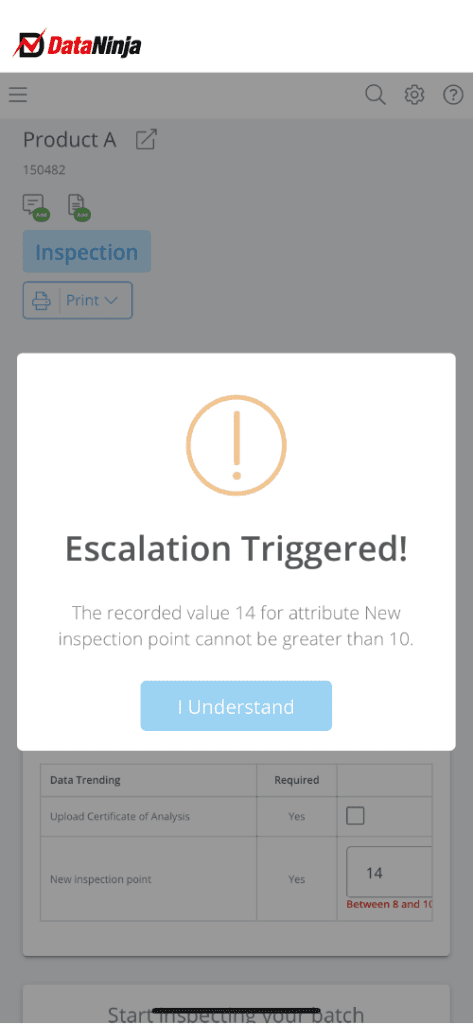

- Allow, halt, or require escalated batch approval based on custom manufacturing process variable thresholds

- A powerful resource for isolating production variability

- Remove the inefficient variables so you can focus on the process and not the paper

Providing tractability regarding the QA status and release state of all inventory coming through the receiving docks is your area. Making sure everyone remembers which materials are permitted to be release for production is very challenging (especially if you are not around for the night shift). DataNinja integrated 2D barcoding and Real-Time analysis engine prevents costly errors.

- Each subset of a Lot receives a unique ID with location, quantity and release state attributes pedigreed to the parent Lot

- Always verifying the correct Part and Lot information

- Verification checks reduce costly errors and rework

DataNinja will help you know the milestone progress of every batch in production. With DataNinja your task of securing the proper documentation at each phase in the process will be reinforced with electronic signatures and automated verification.

- DataNinja eliminates the dependence on an error-prone paper trail investigation

- Electronic Production Records

- Powerful Recipe block uploader for electronic use of existing paper documentation formats

Maintaining production equipment is essential for high quality throughput. DataNinja can help with maintenance reporting, collaboration, and tracking.

- Ensure that the appropriate equipment is to be used and is in the appropriate line clearance state

- Maintenance teams can collaborate across shifts

- Overall Equipment Effectiveness is tracked while Preventative Maintenance schedules are enforced