The Dilemma

Traditional tools did not allow for cost effective data gathering process. Data is costly, yet insights are invaluable. The manufacturing sector has cost pressures from every angle and the only ones who survive are those who can cost effectively collect, analyze, and compete on the data. But how do you squeeze perfect decisions out of imperfect data? Data tied up on paper is error prone and expensive to utilize.

The Solution

DataNinja is data delivered. It is the most economical way to gain competitive advantage from raw source data through variance analysis and efficiency process improvement. By tying into master data with advanced querying. DataNinja brings the clean data you need. With clean input data, analysts and spreadsheet ninjas can distill the data into insights and with those insights compete.

A solution for every role.

With business growth effectively managing the supply chain requires more attention to the big picture. DataNinja is compatible with your efforts to make smart, data-driven decisions.

- DataNinja Sublot traceability through both docks provides a living picture of your inventory velocity

- Your data delivered in paperless form has never been easier for supply chain logistics

- Custom yield alerts and approvals for constant verification of Lot, Part and Sublot information

Your manufacturing process is complex but the management of your data for reporting does not need to be.

- View your multi-dimensional manufacturing data from different angles for quick analysis, and deep study

- DataNinja makes it easy to identify trends and causes of manufacturing variability across Lots

- Custom alerts and approvals flag when deeper investigation might be required

Don’t just compete with your competitors, win with DataNinja. You can use your manufacturing data to streamline operations, and gain competitive advantage as you compete with the data.

- View all inventory history of abnormal batch yields

- Electronic data make s it easy to compare and contrast attributes across multiple or groups of multiople finished goods

- The data is not locked away in static records of but is available for analysis in a full consumption pedigree

Connected data solves problems. DataNinja delivers a rich experience for root cause analysis with Real-time, and historical information.

- Assists in manufacturing variance analysis efforts

- Identify, collaborate, then implement changes based on trended data

- Leverage a quality system that enables management by exemption

Questions? Lets talk.

Request Demo

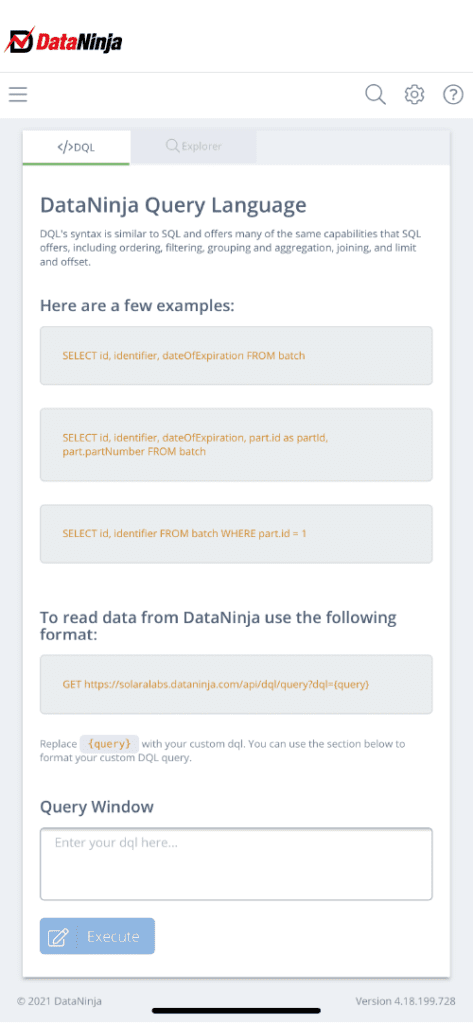

Query Language

Ninja through your data

What used to be scattered across paper and shared spreadsheets is now at your fingertips. What improvements will you uncover next?

Win with Data

Uncover trend across production runs to discover root causes. Is a supplier underfilling? Which line averages the most waste?

A Modern Cloud

Leverage the power of the cloud for access to heavy datasets at the speed of business. Use the REST API for custom integrations and reporting.Get started with your personalized demo.

See how it could work for you- book a demo with one of our experts and we’ll show you what the quality operations management platform can do.

Here’s what to do

+ Fill in your details and click “Submit”

+ We’ll get in touch to book a date and time

for a demo.

+ On the day, we’ll walk you through the platform

and show you how it all comes together.